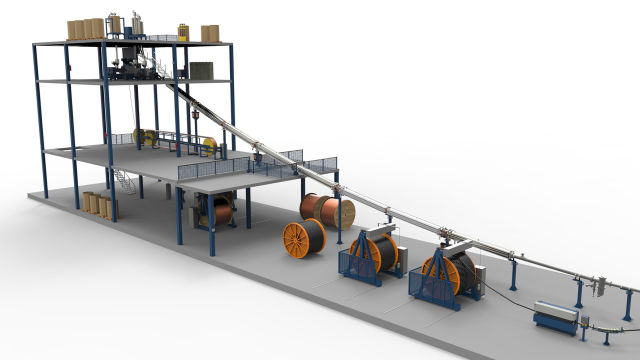

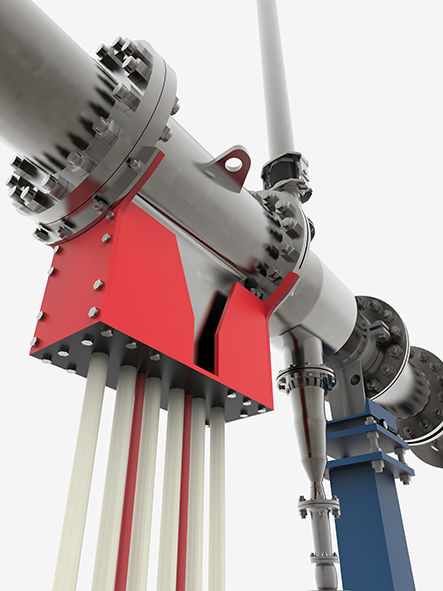

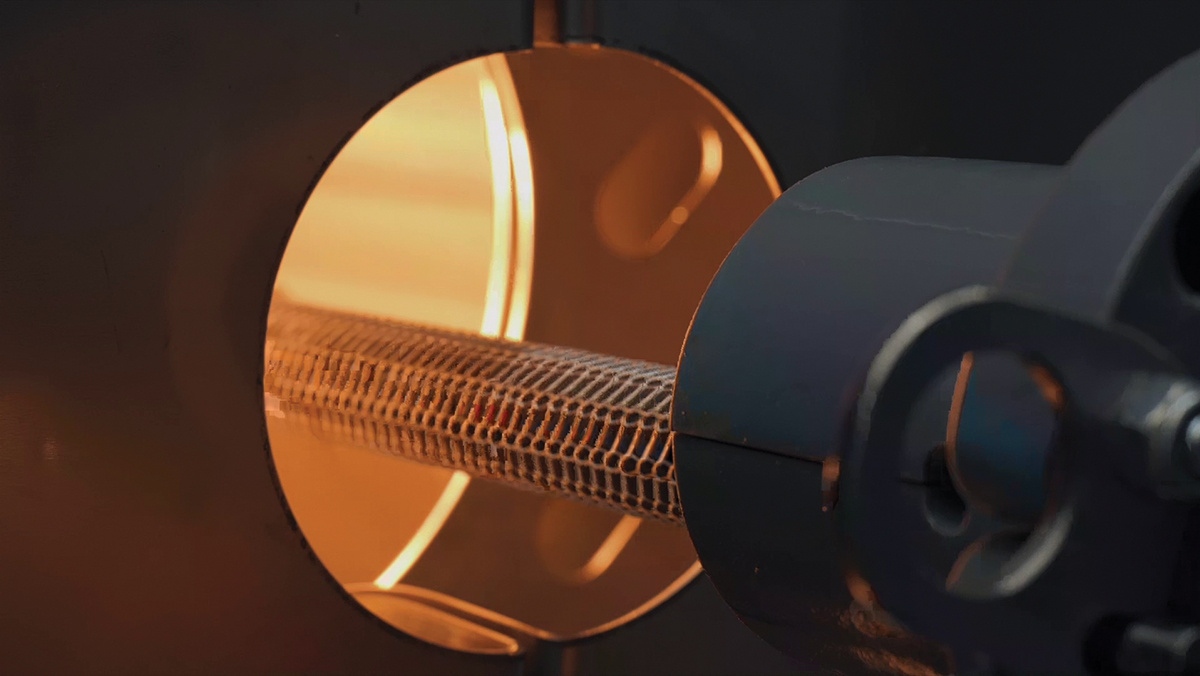

High and extra high voltage cables have important insulation thicknesses, and considerable insulation weight is supported by a small conductor. If the viscosity of the material close to the conductor decreases, as is the case when the temperature increases rapidly, significant drooping occurs and the insulation will be off-centered. In addition to eliminating the drooping effect, our patented method increases heating and cross-linking capacity, and thus line speeds, in catenary continuous vulcanizing lines for medium, high and extra high voltage cable production.

25% faster line speeds with postheating in neutral zone. Also, the reduced heating length enables lower extruder platform heights and lower manufacturing costs.

9.4.2025

Serving multiple markets like heating & plumbing, fiber-optics microducts, medical tubes, automotive tubes, oil & gas and more, means building on commonalities and responding to the specificities. Read more

20.3.2025

In the rapidly evolving field of optical fiber manufacturing, efficiency, precision, and quality are paramount. AI is in place to revolutionize the OF cable manufacturing process. Read more

26.2.2025

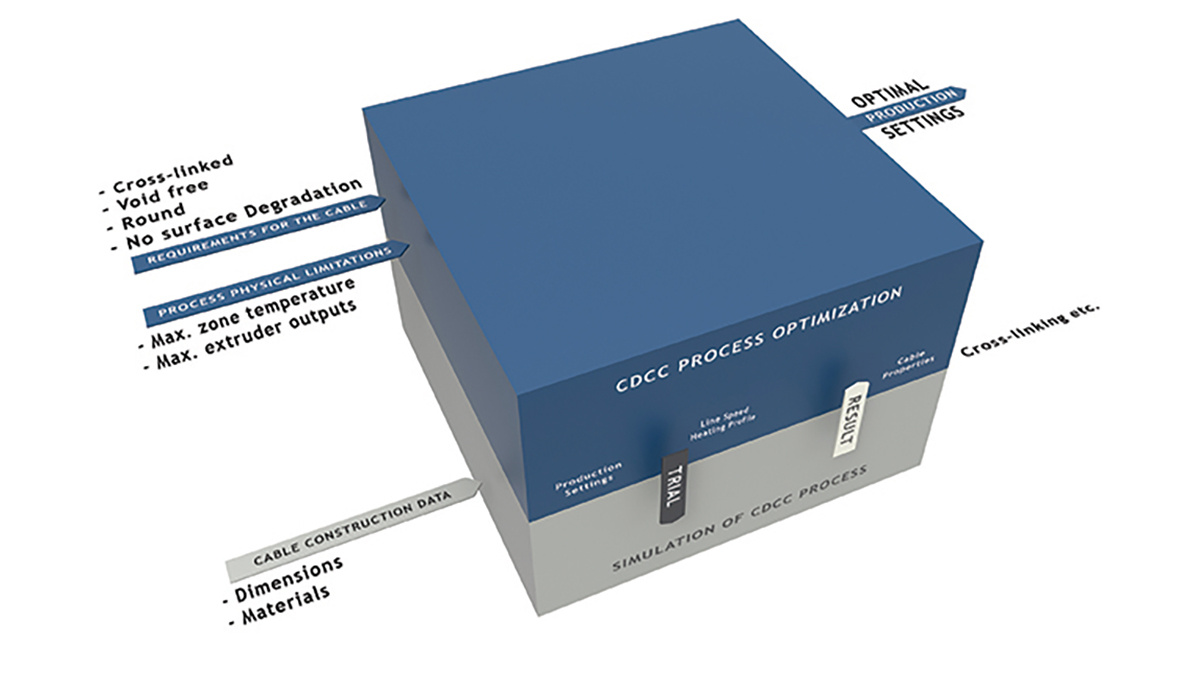

Online Curing Control helps manage cable curing in real time using live measurements. This digital concept relies on process modeling to further reduce scrap and cable defects. Read more

14.2.2025

With electric vehicles, the demand is for light weight, recyclable tube constructions. The transition is taking place as we help customers shift from rubber compounds to thermoplastic elastomers. Read more

29.1.2025

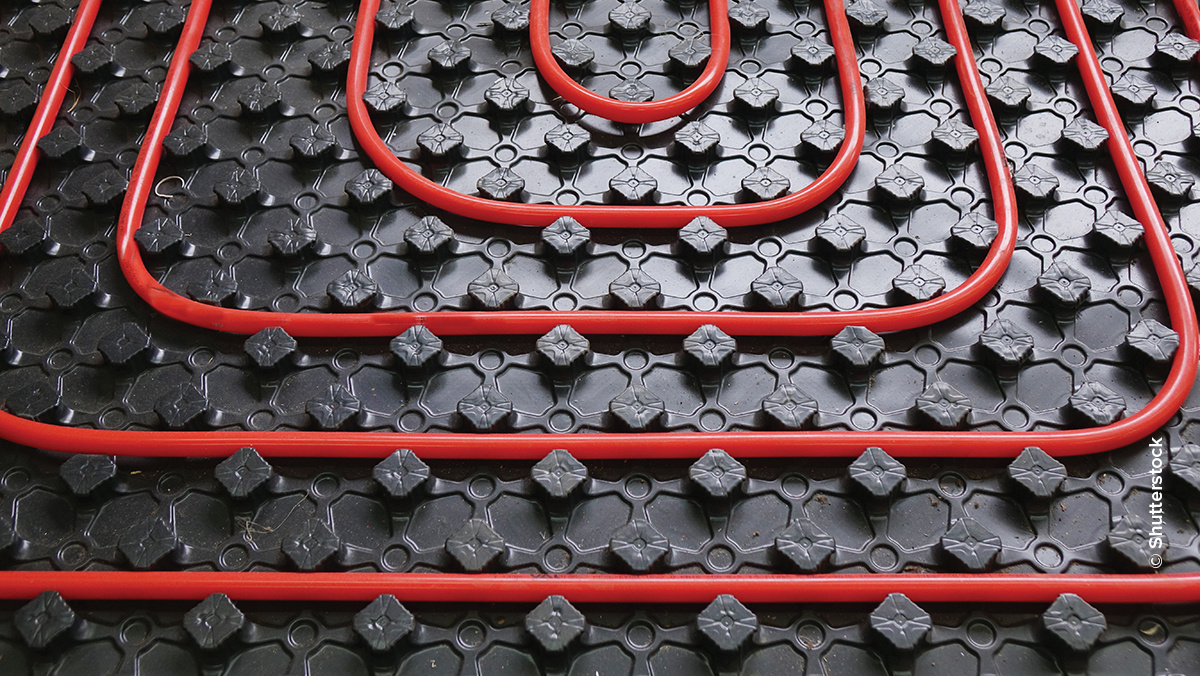

EVOH demand heightens, and prices climb. Maillefer teams up with suppliers so that manufacturers can make more multi-layer PEX or PE-RT pipe with less. Read more

20.1.2025

We have expanded the fiber optic portfolio for indoor cables. This new line produces all types including tight buffers, simplex/ duplex, drop cables and distribution cables. Read more

7.1.2025

Strong, active partnerships build customer success in Maillefer’s “House of Experts” concept. There is a constant dialogue for cable & pipe extrusion performance to its optimum. Read more

17.12.2024

The formidable project is entitled NEWGEN. It is funded by the EU’s Horizon 2020 research and innovation program. Our R&D platform is helping set the benchmark for HVDC PP cable. Read more