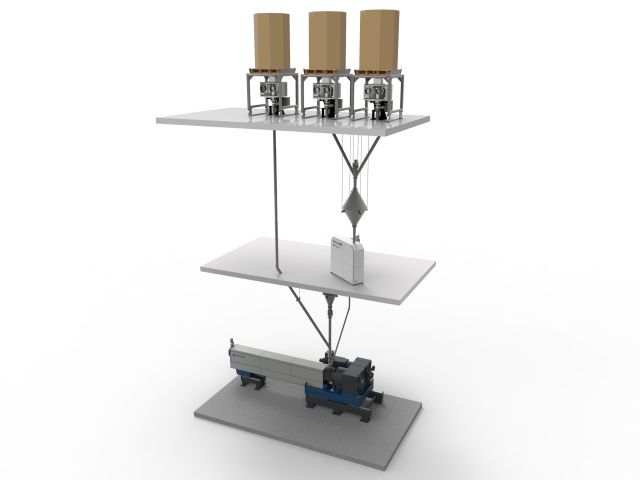

While your compound suppliers provide clean XLPE insulation compounds, with our clean-run value package these compounds are kept clean. In fact, they are made even cleaner through the material conveying from the package to the extruder.

Removal of contaminants, which results in clean compounds.

15.5.2024

EHVDC is the cable of choice for renewable energy distribution. Optimizing the curing process while producing the cable is a responsible way to deal with by-products. Maillefer and Borealis team up for this white paper. Read more

6.5.2024

The RCB 150 haul-off has been specially designed to pull flexible and rigid pipes. This robust caterpillar is ideal in a jacketing line configuration for microduct bundles. Read more

29.4.2024

23.4.2024

Production processes, machinery, and maintenance practices have developed over time. The wealth of know-how acquired is available for you via our Consultation offering. Read more

12.4.2024

New automotive tube types are in demand, including those made with thermoplastic elastomer. Indeed, a dual-layer reinforced TPV construction is occupying an important place in today’s EV cooling circuits. Read more

22.3.2024

Wanma Cable has hybrid ability for producing both classic XLPE power cables and ones made of PP-TPE reserved for green energy. Thanks to the important development efforts realized on our CV extrusion line. Read more

22.2.2024

There's a choice to be made when balancing screw performance to processing requirements. A perfect set of screw parameters may translate to energy savings Read more

12.2.2024

The move from Internal Combustion Engine (ICE) vehicles towards ones driven by alternative energy sources is in full swing. Nations have targeted a complete phase out in 2050 with an end for all new cars in 2035 (i.e. the Declaration of Glasgow). Several countries have undertaken more aggressive measures to accelerate the transition, notably Norway and Singapore. Hybrid, battery and fuel cell Electric Vehicle (EV) production is gearing up in factories around the world. The arrival of the new technology is sending waves of change along the entire supply chain. Read more