Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

#1 Extrusion Drive<br />

CT 06379 Pawcatuck

Tel: +1 860 625 48 45

com;rd.;nda;sta;is-;dav;uk/;jwnMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

net;ns.;tio;olu;ons;usi;xtr;y/e;troInterested in developing your cable production process with no risks and no interruptions?

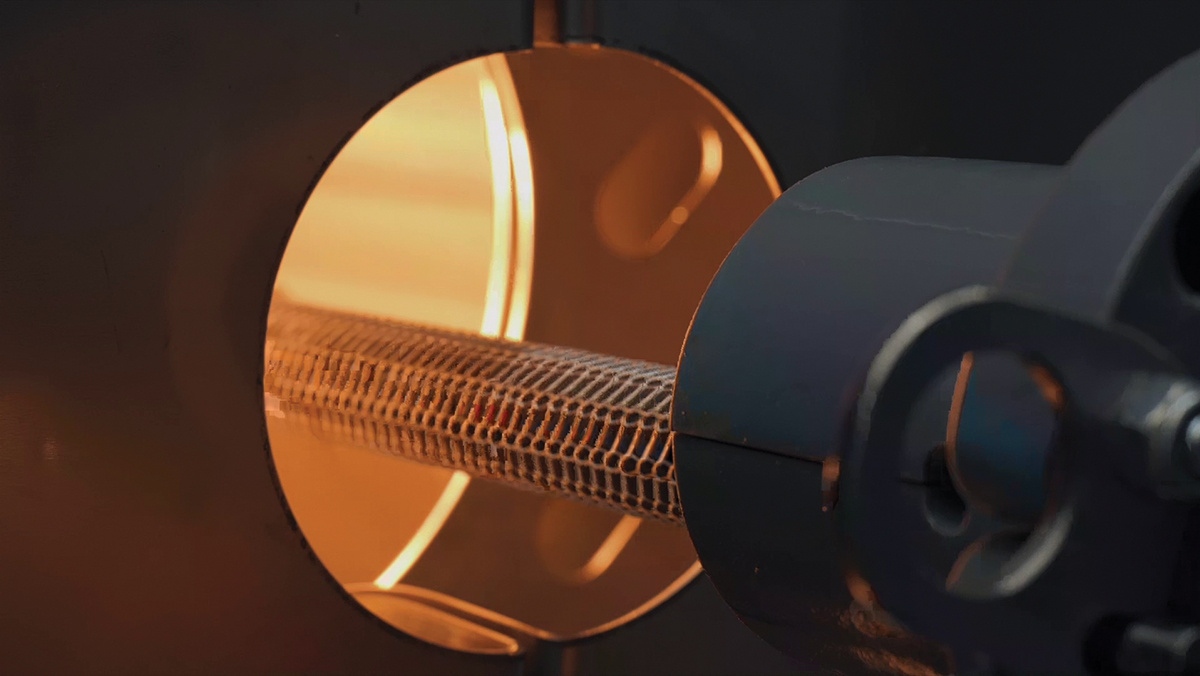

The world’s only vertical pilot curing line for medium, high and extra high voltage cables is available for accelerated trials in Maillefer’s R&D Center in Finland. You can rent the line for a day and get the possibility to test your ideas and pilot new technologies with two experienced experts.

Several cable issues are only visible after the curing process. The Maillefer vertical pilot line is equipped with a full-scale extrusion group capable of producing model cables up to 750 kV at realistic line speeds. It also has a curing tube for model cable curing as part of the process as well as Clean Room. The line requires significantly less material for a trial run than a real production line.

The Vertical Pilot Line consists of the following equipment:

One-day Vertical Pilot Line use for idea testing and technology piloting including two Maillefer’s operators. The full-scale facilities to develop the cable production as a whole.

Recommendation and consultation for but not limited to:

Please fill in your details below and we’ll get in touch!

20.3.2025

In the rapidly evolving field of optical fiber manufacturing, efficiency, precision, and quality are paramount. AI is in place to revolutionize the OF cable manufacturing process. Read more

26.2.2025

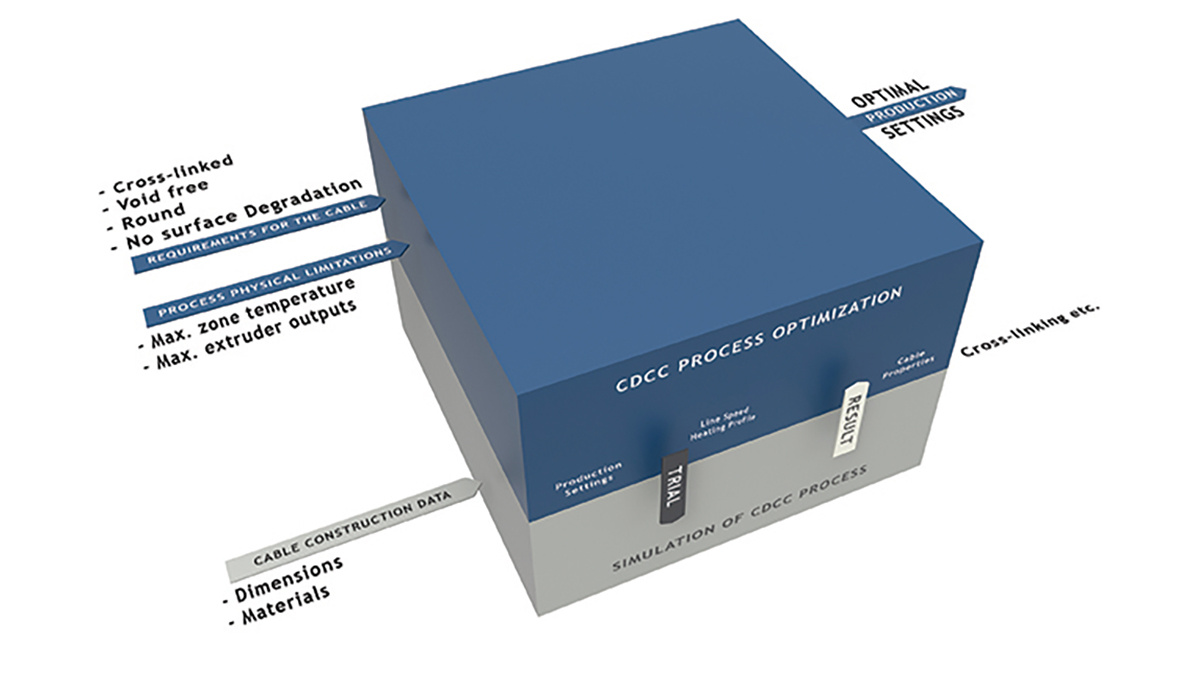

Online Curing Control helps manage cable curing in real time using live measurements. This digital concept relies on process modeling to further reduce scrap and cable defects. Read more

14.2.2025

With electric vehicles, the demand is for light weight, recyclable tube constructions. The transition is taking place as we help customers shift from rubber compounds to thermoplastic elastomers. Read more

29.1.2025

EVOH demand heightens, and prices climb. Maillefer teams up with suppliers so that manufacturers can make more multi-layer PEX or PE-RT pipe with less. Read more

20.1.2025

We have expanded the fiber optic portfolio for indoor cables. This new line produces all types including tight buffers, simplex/ duplex, drop cables and distribution cables. Read more

7.1.2025

Strong, active partnerships build customer success in Maillefer’s “House of Experts” concept. There is a constant dialogue for cable & pipe extrusion performance to its optimum. Read more

17.12.2024

The formidable project is entitled NEWGEN. It is funded by the EU’s Horizon 2020 research and innovation program. Our R&D platform is helping set the benchmark for HVDC PP cable. Read more

28.11.2024

Extrusion efficiency needs to be considered when producing pipe, tube, wire & cable for infrastructure and transportation. The aim is to avoid unwanted waste. Read more