Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

Phipps Bend Industrial Park<br />

402 Phipps Bend Road

TN 37873 Surgoinsville

Tel: +1 423 817 2440

Fax: +1 423 212 0131

om;a.c;rus;efe;ill;/ma;jonMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

net;ns.;tio;olu;ons;usi;xtr;y/e;troOur line control software are advanced, modular and expandable control sysmtems which provide structured and user friendly ways to operate, control, monitor and manage your valuable production.

Our Line Control Autoextrusion 4.1S slimline (AE 4.1S) provides control of the extrusion line, monitoring of the machines, prodcution follow-up with an extended production management system and assures a user friendly operator interface. It enhances the productivity and reliability of the production line as well as the quality of the final product.

The AE 4.1S a Line Control Unit (LCU) with a fail safe Siemens PLC, an industrial field bus for controlling distributed I/O and drives, a user friendly movable control panel with a Siemens touch panel. The software contains all logical sequences and calculations for performing, such as machines selection and interlocking, line sequences, synchronization of all machines, temperature control loops, system diagnostic of hardware modules and bus nodes.

Process monitoring

The process monitoring provides a simple intuitive and highly interactive interface. Through animated objects, touch buttons, trend charts, coloured images, the operator gets online information of the ongoing process. Images, control panels and all objects are designed to exactly fit the production line providing all necessary information needed in the process.

Main features

The AE 4.1S operator interface includes simple process monitoring with measurement and state displays, and setvalue and command handlings, basic alarm handling showing active alarms with clear text, and a basic recipe system which enables production parameters to be saved and recalled when required.

Remote service

The remote service connection is made in a secure way via internet or GPRS/EDGE connection. It gives the possibility to make remote service, diagnostic, software update and troubleshooting functions for the line automation system, almost in a similar way as with a local connection. The remote service includes the required hardware and the functionality tests of the connection. If the GPRS/EDGE connection is used, the customer must provide the required SIM-card. The price of the remote service is negotiated case by case.

15.5.2024

EHVDC is the cable of choice for renewable energy distribution. Optimizing the curing process while producing the cable is a responsible way to deal with by-products. Maillefer and Borealis team up for this white paper. Read more

6.5.2024

The RCB 150 haul-off has been specially designed to pull flexible and rigid pipes. This robust caterpillar is ideal in a jacketing line configuration for microduct bundles. Read more

29.4.2024

23.4.2024

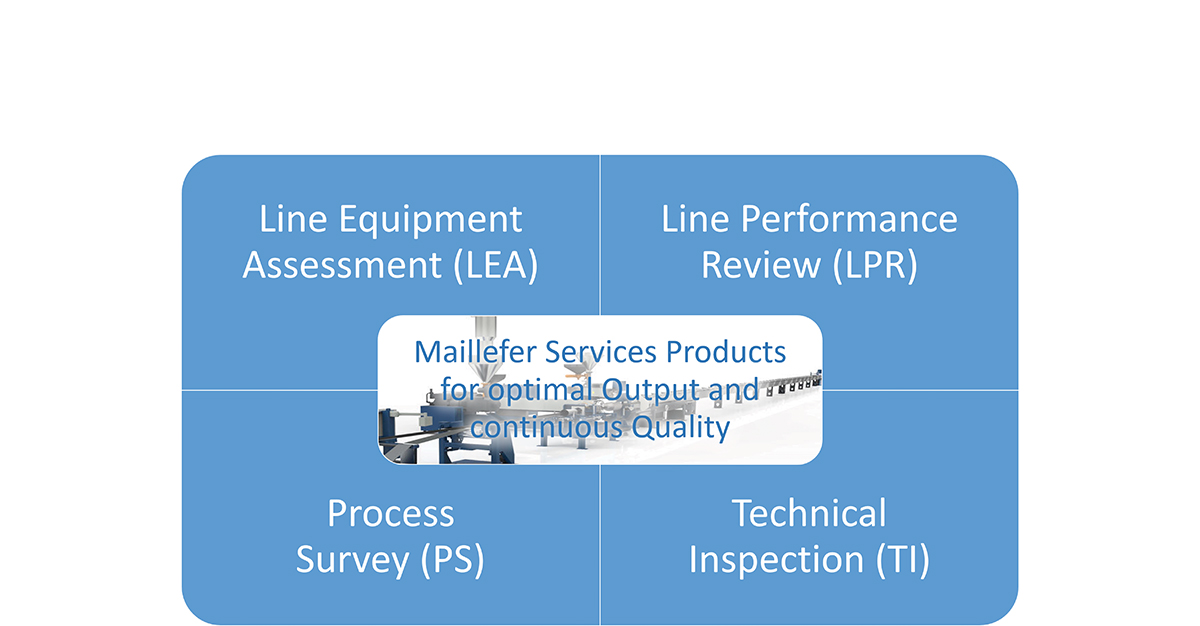

Production processes, machinery, and maintenance practices have developed over time. The wealth of know-how acquired is available for you via our Consultation offering. Read more

12.4.2024

New automotive tube types are in demand, including those made with thermoplastic elastomer. Indeed, a dual-layer reinforced TPV construction is occupying an important place in today’s EV cooling circuits. Read more

22.3.2024

Wanma Cable has hybrid ability for producing both classic XLPE power cables and ones made of PP-TPE reserved for green energy. Thanks to the important development efforts realized on our CV extrusion line. Read more

22.2.2024

There's a choice to be made when balancing screw performance to processing requirements. A perfect set of screw parameters may translate to energy savings Read more

12.2.2024

The move from Internal Combustion Engine (ICE) vehicles towards ones driven by alternative energy sources is in full swing. Nations have targeted a complete phase out in 2050 with an end for all new cars in 2035 (i.e. the Declaration of Glasgow). Several countries have undertaken more aggressive measures to accelerate the transition, notably Norway and Singapore. Hybrid, battery and fuel cell Electric Vehicle (EV) production is gearing up in factories around the world. The arrival of the new technology is sending waves of change along the entire supply chain. Read more