Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

#1 Extrusion Drive<br />

CT 06379 Pawcatuck

Tel: +1 860 625 48 45

com;rd.;nda;sta;is-;dav;uk/;jwnMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

net;ns.;tio;olu;ons;usi;xtr;y/e;troWith our fiber optic Lay-plate Strander SZF you get high rotating speed combined to optimized turning points. This makes it possible to get high productivity with all different loose tube sizes and cable designs.

Our Lay-plate Strander SZF is designed for high speed SZ-stranding of loose tubes or optic fibres with a capacity of 4 - 24 loose tubes. The Stranding method is based on lay plates. It ensures constant tension and even lay length in all production speeds and trough out the manufactured cable. The machine contains 17 lay plates and a stranding head which allows the machine to perform 18 revolutions per direction. The maximum rotation speed of the stranding head is +/-2200 rpm.

| Number of stranding discs | 17 pcs |

| Lay Length | 40 - 1000 mm |

| Speed, max. | 200 m/min |

| Rotation speed for stranding, max. | 2200 rpm |

Exact values depend on the assembly.

9.4.2025

Serving multiple markets like heating & plumbing, fiber-optics microducts, medical tubes, automotive tubes, oil & gas and more, means building on commonalities and responding to the specificities. Read more

20.3.2025

In the rapidly evolving field of optical fiber manufacturing, efficiency, precision, and quality are paramount. AI is in place to revolutionize the OF cable manufacturing process. Read more

26.2.2025

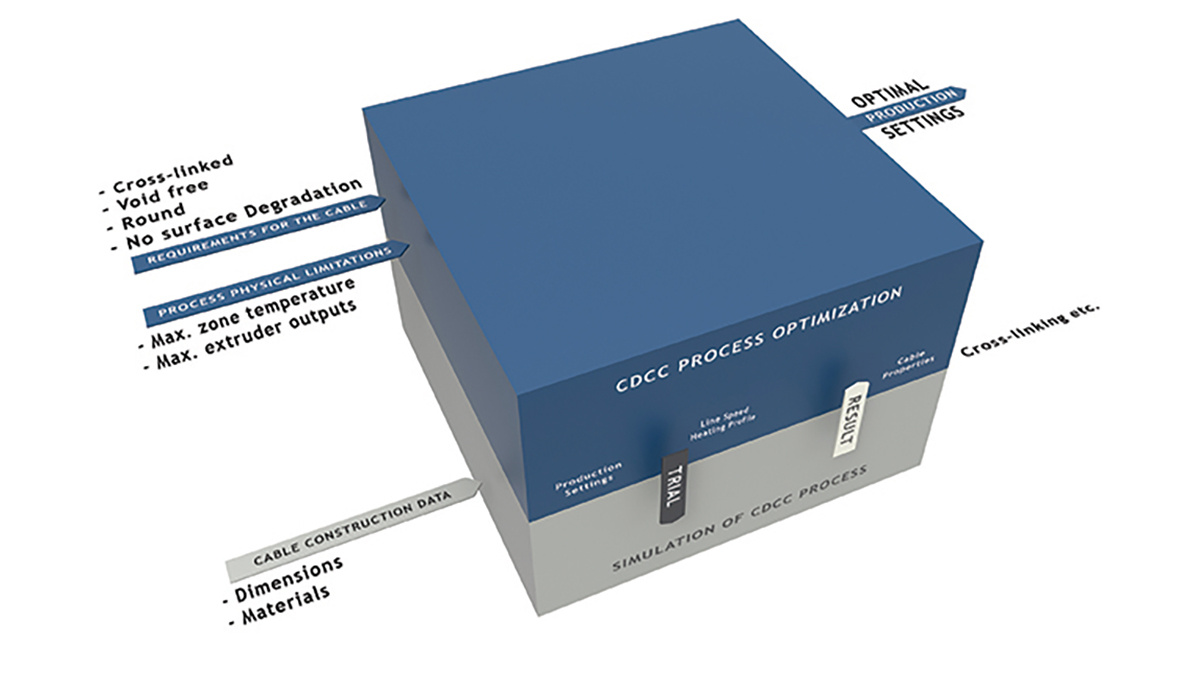

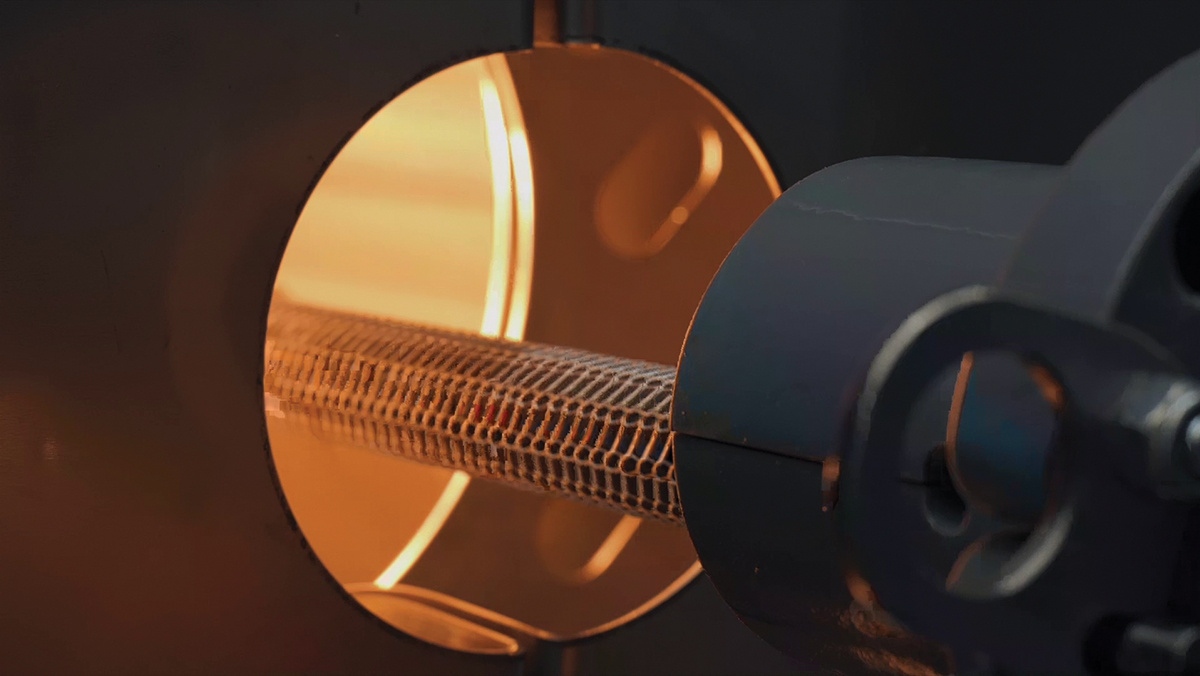

Online Curing Control helps manage cable curing in real time using live measurements. This digital concept relies on process modeling to further reduce scrap and cable defects. Read more

14.2.2025

With electric vehicles, the demand is for light weight, recyclable tube constructions. The transition is taking place as we help customers shift from rubber compounds to thermoplastic elastomers. Read more

29.1.2025

EVOH demand heightens, and prices climb. Maillefer teams up with suppliers so that manufacturers can make more multi-layer PEX or PE-RT pipe with less. Read more

20.1.2025

We have expanded the fiber optic portfolio for indoor cables. This new line produces all types including tight buffers, simplex/ duplex, drop cables and distribution cables. Read more

7.1.2025

Strong, active partnerships build customer success in Maillefer’s “House of Experts” concept. There is a constant dialogue for cable & pipe extrusion performance to its optimum. Read more

17.12.2024

The formidable project is entitled NEWGEN. It is funded by the EU’s Horizon 2020 research and innovation program. Our R&D platform is helping set the benchmark for HVDC PP cable. Read more